About Welding Solutions

BIRJA TECHNOLOGIES offers a wide range of high-performance welding components designed for industries where reliability and wear resistance are critical. Our products are engineered to withstand extreme environments, heavy loads, and abrasive operations—making them ideal for mining, cement, construction, and sugar industries.

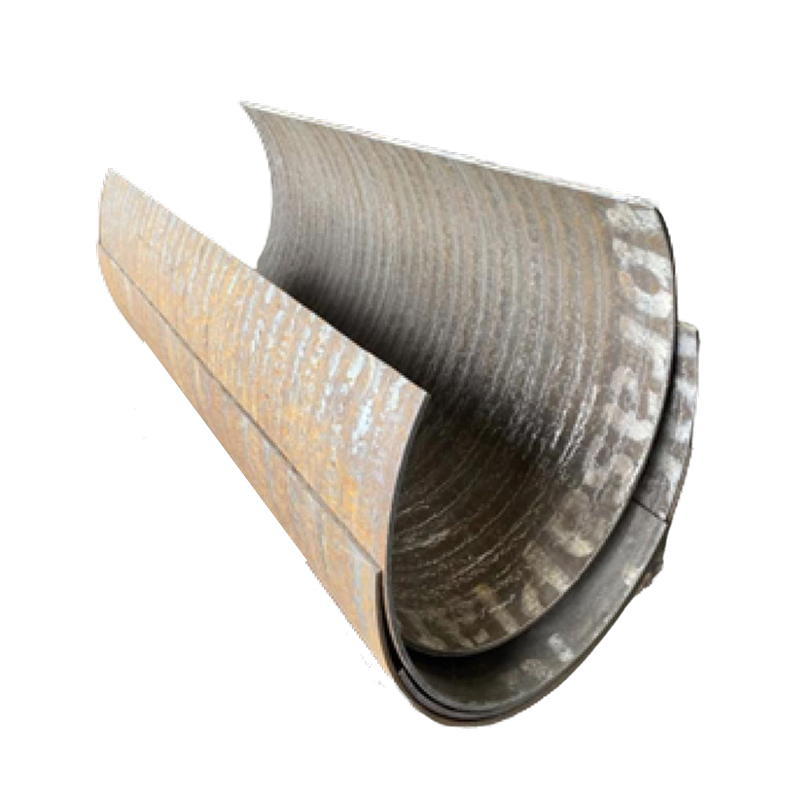

Wear-Resistant Parts

- Toggle Plate for Jaw Crusher

- Side Plate for Jaw Crusher

- Chain Carrier

- Mixer Liner

- Mixer Arm

- Screen Plate

- Circular Screen Plate

- Mixer Bottom Liner

- Mixer Side Liner

- Feed Tube Liner

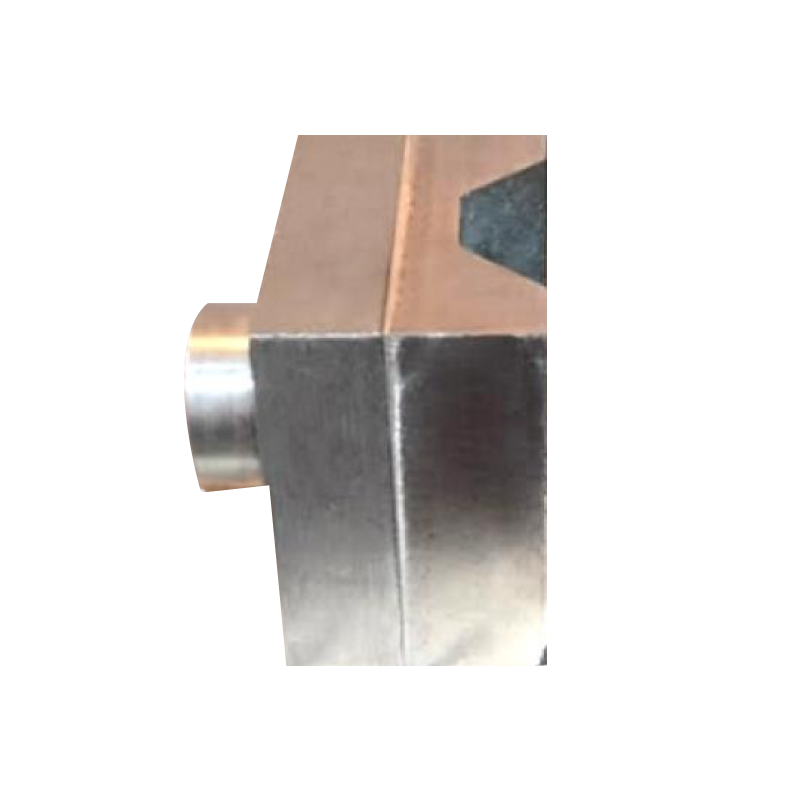

Welded Overlay Solutions

- Base MOC and Thickness: ‘X’ mm

- Overlay MOC and Thickness: ‘Y’ mm

Sugar Plant Wear Parts

- Hammer Body

- Hammer Knife

- Hammer Inserts

- Metal Matrix Hammer

- Knife Inserts

Our Expertise

- Decades of experience in fabrication & metallurgy

- Proven solutions for high-impact and abrasive environments

- Use of premium-grade Base & Overlay materials

- Customization as per client specs and application needs

- Advanced quality control to ensure dimensional precision and durability

Wear-Resistant Parts

- Toggle Plate for Jaw Crusher

- Side Plate for Jaw Crusher

- Chain Carrier

- Mixer Liner

- Mixer Arm

- Screen Plate

- Circular Screen Plate

- Mixer Bottom Liner

- Mixer Side Liner

- Feed Tube Liner

Welded Overlay Solutions

- Base MOC and Thickness: ‘X’ mm

- Overlay MOC and Thickness: ‘Y’ mm

Sugar Plant Wear Parts

- Hammer Body

- Hammer Knife

- Hammer Inserts

- Metal Matrix Hammer

- Knife Inserts

Wear-Resistant Parts

Welded Overlay Solutions

Sugar Plant Wear Parts

Wear-Resistant Parts

Welded Overlay Solutions

Sugar Plant Wear Parts

| HAMMER INSERT SIZES | |||||

|---|---|---|---|---|---|

| ITEM CODE | LENGTH | WIDTH | CARBIDE THICKNESS | IS:2062 THICKNESS | TOTAL WEIGHT |

| 100100A | 100 | 100 | 35 | 20 | 4.4 |

| 100100B | 100 | 100 | 35 | 20 | 4.4 |

| 9090A | 90 | 90 | 35 | 20 | 3.5 |

| 9090B | 90 | 90 | 35 | 20 | 3.5 |

| 9070A | 90 | 70 | 35 | 20 | 2.7 |

| 9070B | 90 | 70 | 35 | 20 | 2.7 |

| 9050A | 90 | 50 | 35 | 20 | 2 |

| 9050B | 90 | 50 | 35 | 20 | 2 |

| 8080A | 80 | 80 | 35 | 20 | 2.8 |

| 8080B | 80 | 80 | 35 | 20 | 2.8 |

| 8060A | 80 | 60 | 35 | 20 | 2 |

| 8060B | 80 | 60 | 35 | 20 | 2 |

| 8056A | 80 | 56 | 35 | 20 | 2 |

| 8056B | 80 | 56 | 35 | 20 | 2 |

| 7070A | 70 | 70 | 35 | 20 | 2.1 |

| 7070B | 70 | 70 | 35 | 20 | 2.1 |

| 6060A | 60 | 60 | 35 | 20 | 1.6 |

| 6060B | 60 | 60 | 35 | 20 | 1.6 |

| KNIFE INSERTS & KNIFE BAR | |||||

|---|---|---|---|---|---|

| PART NO. | DIMENSIONS | ||||

| A | B | C | D | E | |

| SVS200 | 200 | 5-10 | 25-45-65 | 15 | 25-30-40 |

| SVS250 | 250 | 5-10 | 25-45-65 | 15 | 25-30-40 |

| SVS300 | 300 | 5-10 | 25-45-65 | 15 | 25-30-40 |

| SVS350 | 350 | 5-10 | 25-45-65 | 15 | 25-30-40 |

| SVS400 | 400 | 5-10 | 25-45-65 | 15 | 25-30-40 |

Looking for a custom quote, detailed specifications, or expert consultation?

We’re ready to deliver the solution you need.